Cargo Security and protection

in container or truck

Thermo liners Dunnage bags Desiccants Plastic Slip Sheets

Plastic pallets Lashing and webbing Antislip mats Kraftliner Slip Sheet

Soapck offers Cargo Security and protection in container or truck

Sopack s.r.o. offers a complete product portfolio for fixing and securing the container. We offer air fixation bags, thermoregulation pads, harnesses, belts, anti-slip pads, desiccants, anti-slip pads, container pads, slip sheet pads and more.

- Dunnage bags/ Air bags for filling gaps up to 45 cm

- 3D Dunnage bags/air bags for filling gaps up to 80 cm

- Thermo liners for temperature control in the container

- Desiccants for optimal humidity

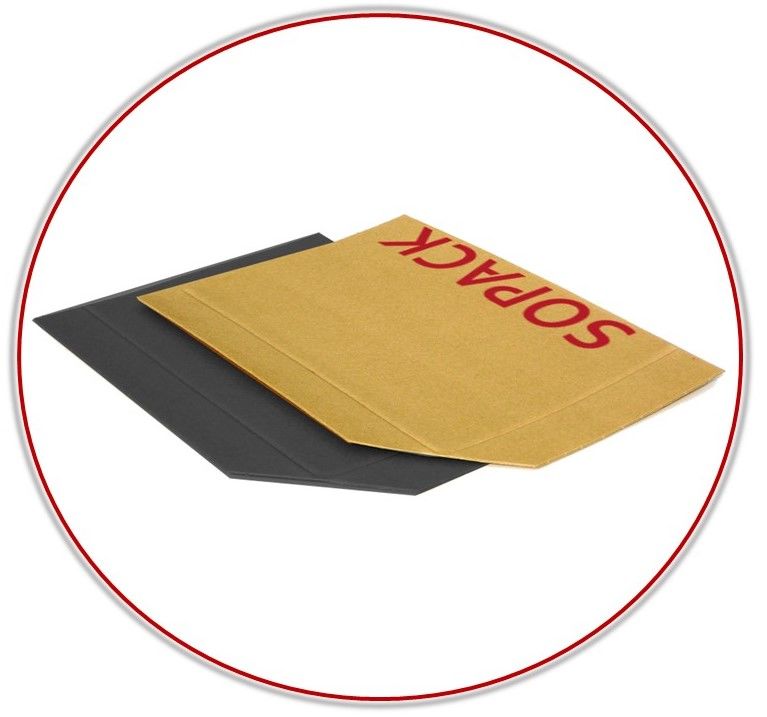

- Slip Sheets for transport without pallets

- Plastic pallets alternative to wooden pallets without the need for a certificate

- Lashing and webbing for fixing goods

- Anti-slip mats for higher friction between the pallet and the floor

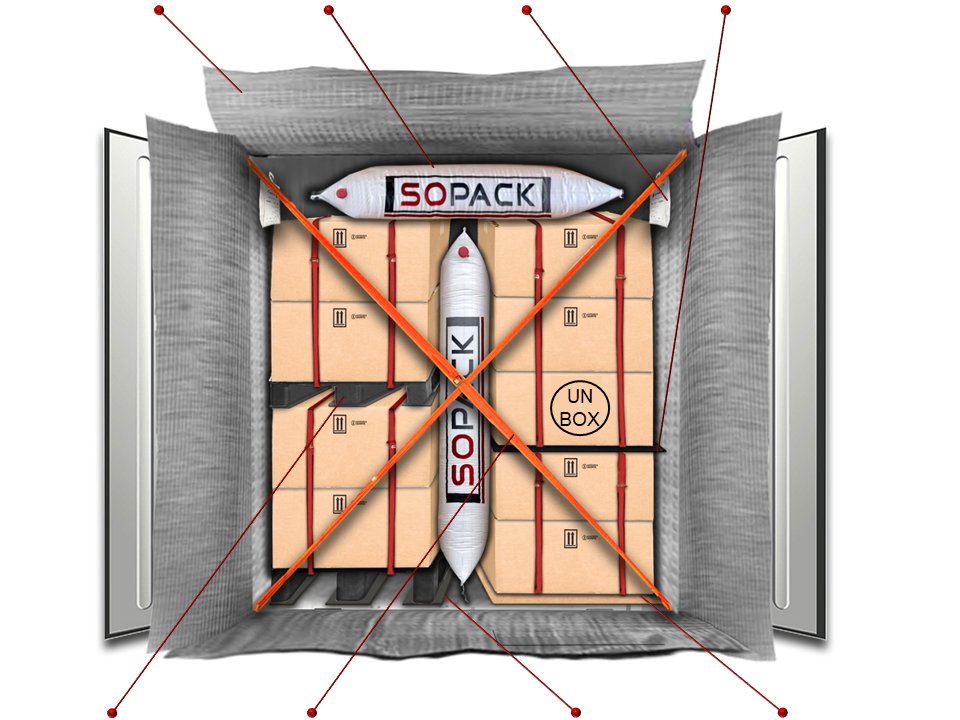

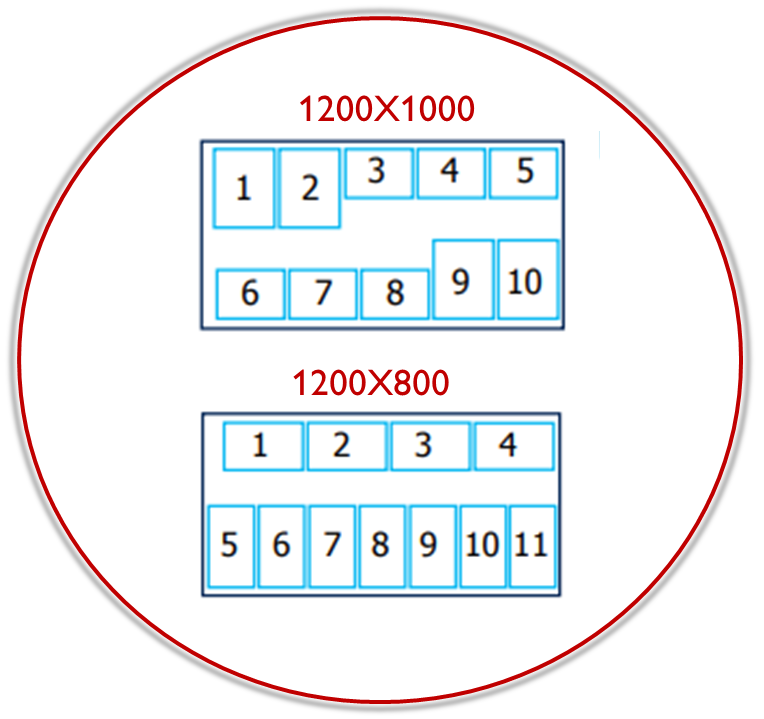

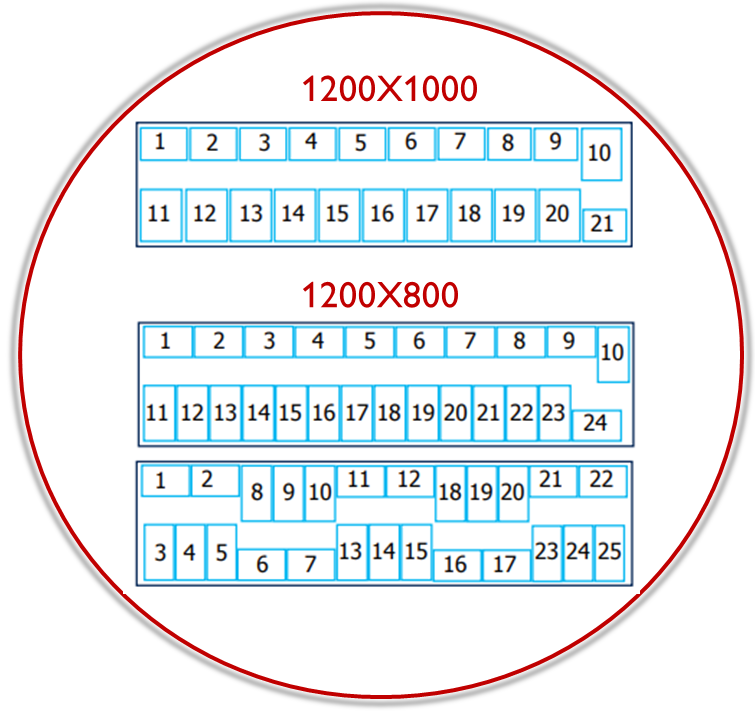

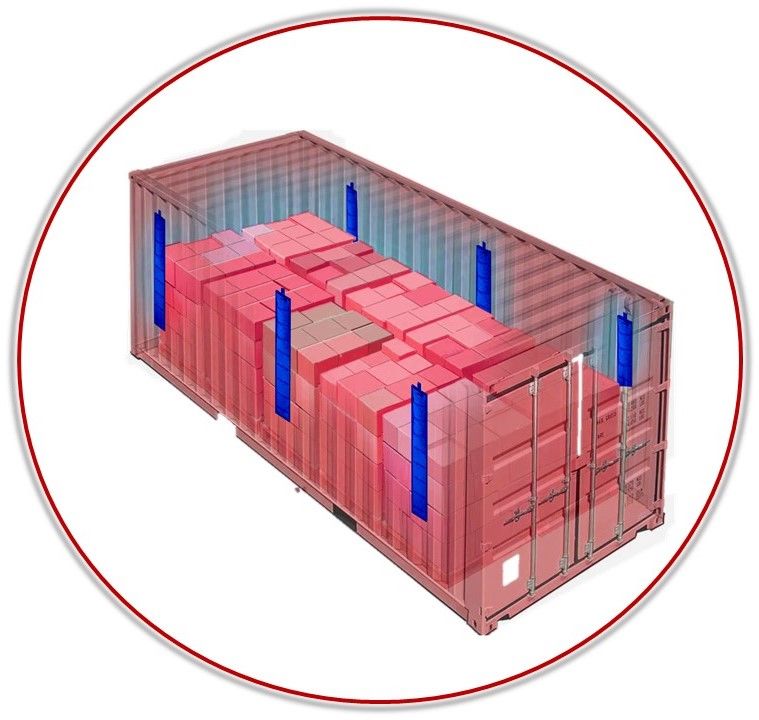

Fixation and suitable loading of pallets in a container

The Sopack team is ready to help you with the appropriate container loading so that the shipping container is as busy as possible. Alternatively, it is possible to use software that will help you define the correct loading of pallets in the container.

20 ft container

40 ft container

Calculation of container forces in intermodal transport

The Sopack team is ready to help you with the design and calculation of forces in the container, when fixing the goods in the container, it is necessary to find out the way the container will travel and calculate the forces to which the container is to be fixed. According to the statistics of control authorities, today 25% of containers exported from the EU are insufficiently secured and up to 60% of sea containers are imported into the EU. The calculation of forces in the container is defined using the standards of individual states, or CTU Code (Cargo Transport Unit), AAR Code (Association of American Railroads) UIC, ČD Cargo. It is always necessary to focus on the path of the container

Calculation of forces in a container in rail transport

For the correct fixation of the goods in the railway container, it is necessary to know what forces act on the container and in which directions it is necessary to secure / fix the container. In rail transport, the CTU Code determines the distribution of forces 0.5G forward, 0.5G backward, 0.5G laterally, 0G upwards, however UIC and ČD CARGO have higher requirements, namely 1.0G forward, 1.0G backward, to the side 0.5G, upwards 0.3G

Calculation of container forces in maritime transport

For the correct fixation of the goods in the sea container, it is necessary to know what forces act on the container and in which directions it is necessary to secure / fix the container. In maritime transport, the CTU Code determines the distribution of forces 0.4G forward, 0.4G backward, 0.8G laterally, 0.2G upward

Calculation of forces in a container in freight transport

For the correct fixation of the goods in the sea container on the road, it is necessary to know what forces act on the container and in which directions it is necessary to secure / fix the container. In rail transport, the CTU Code determines the distribution of forces 0.5G forward, 0.5G backward, 0.5G laterally, and 0 G upward.

1. Primary Fixation of goods using dunnage bags / air bags

Sopack s.r.o. offers fixation filling dunnage bags (air bags). Thanks to the wide FAST FLOW valve, filling is fast and efficient. Plastic dunnage bags / air bag 90x210 mm, we are able to fill with air within 35 seconds, using a standard compressor. The air fixation bags have a FAST FLOW valve, to which we will supply you with a metal filling gun, which can be immediately mounted on a common compressor using quick couplings. Air bags offer a great price / performance ratio. With standard dunnage bags air bags, you can easily and quickly fill gaps up to 40 cm.

Dunnage bag selection

To make the right choice, it is necessary to consider the width of the gap, the weight of the pallet, the direction of fixation and the destination.

2. 2. Primary and secondary Fixation of goods using lashing and webbing

Sopack s.r.o. offers multy-ply use lashing, one-time lashing straps and safety sheets for the safe transport of your products. Thanks to a wide portfolio and stock conditions, we can respond quickly to your requirements. We are ready to help you with the recommendation of a suitable mooring or to help devise an anchoring system.

Selection of lashing

It is necessary to calculate the tonnage of the load unit / pallet so that it corresponds to the specifications of the given mooring. At the same time, it is necessary to take into account the stretching of the harnesses so that the individual blocks are not too long. Elongation of ties is standard 3-5%

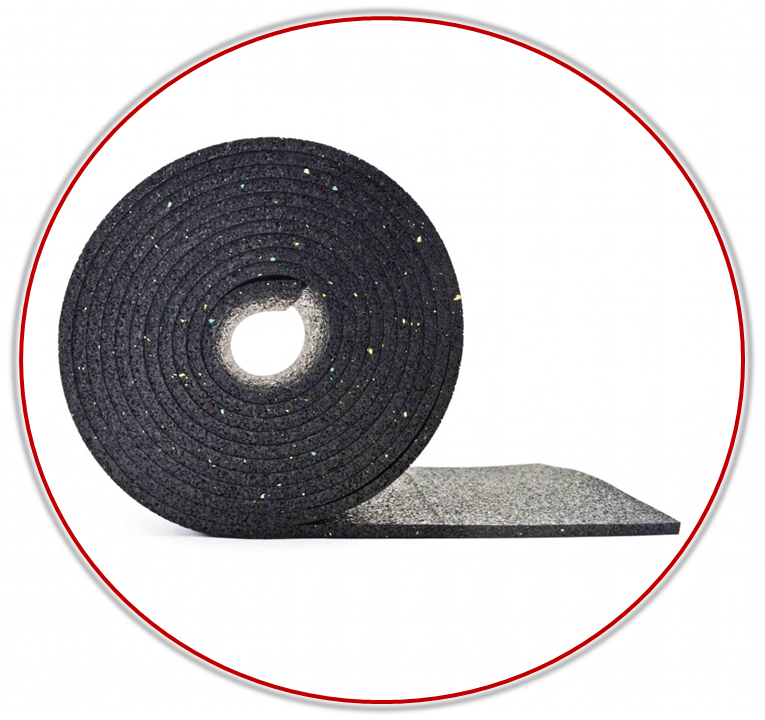

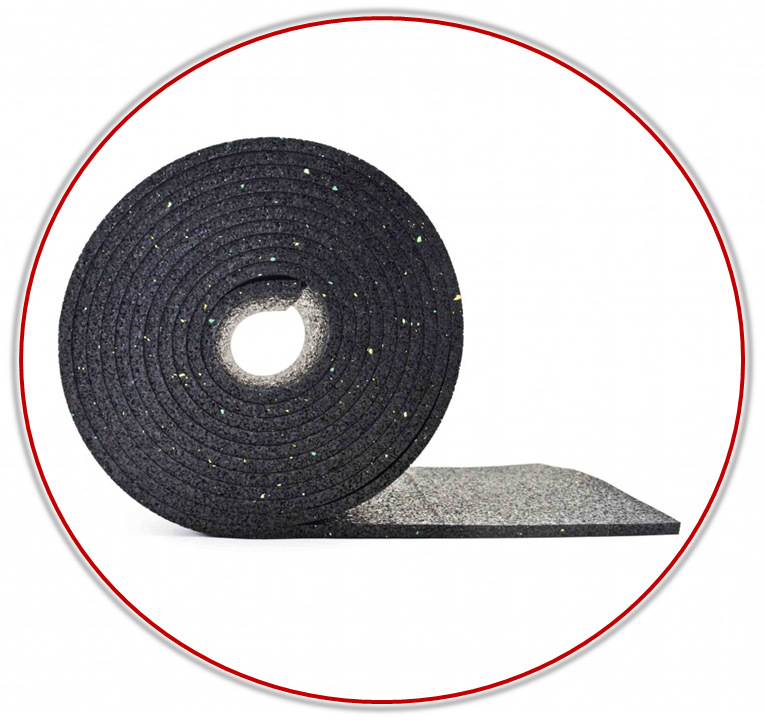

3. Secondary Fixation of goods using anti-slip mats

Sopack s.r.o. offers anti-slip mats. Anti-slip mats and pads prevent impact by increasing friction between the pallet and the container floor, thus preventing dangerous property damage and personal injury. Our mats made of rubber granulate bonded with PU can be used not only in the cargo area of the truck, but also on trailers and can be used in smaller vans weighing 7.5 t.

Selection of anti-slip mat

When choosing a non-slip mat, you should focus on the friction coefficient (Sopack offers pads with a friction coefficient of 0.8), a reputable brand and, of course, the length of the mat. (according to friction force)

How to "simply" assess the static friction force of your load

Static coefficient of friction μ

Dry Wood - Wood - 0.3-0.4

Wet Wood - Wood - 0.2

Wood - Washer - 0.6-0.8

Source: E-konstrukter

When calculating the friction force Ff = μ N, it is necessary to take into account that we are moving in a static dimension, however, real transport is in a dynamic dimension. Therefore, it is necessary to work with the appropriate safety factor. (which must include imperfect contact between the floor and the pallet, the difference between static and dynamic coefficient of friction, wetting, floor grease and others)

4. Securing the container against moisture, abrasion, container rain

Sopack s.r.o. offers desiccants for container., container liners. Products that work against moisture or abrasion and container rain. Desiccants absorb the moisture that is created in the container even by changing temperatures, humidity at sea. Desiccants absorb up to 300% of their own weight. Container inserts secure the container from moisture passage, water / container rain infiltration, odor seepage, possible contamination.

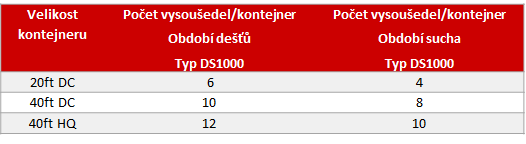

Number of desiccants in the container (according to the manufacturer)

Sopack s.r.o. offers desiccants in a container with higher efficiency up to 300%. It is necessary to emphasize that when choosing a suitable desiccant, the customer must consider some attributes such as:

- Final destination,

- Container route, according to similar passports and seasons.

- Type of goods in the container

- Container condition, door insulation inspection, and others

When calculating the price of container desiccants, it is necessary to calculate the overall efficiency of desiccants, according to the manufacturer's specifications. In order to compare similar desiccant performances.

5. Passive thermoregulation of a container or pallet unit

Sopack s.r.o. offers thermoregulatory liners for containers or thermoregulatory packaging for pallet units. Sopack offers passive protection and thermoregulation of containers or pallets. The primary task of thermoregulatory liners is to capture temperature peaks, fluctuations during container transport. Secondly, thermoregulatory pads protect goods from moisture, container rain odor. Thermoregulating packaging on a pallet isolates goods from the outside environment for shorter transports, but also for container transports.

Efficiency of thermoregulatory packaging in comparison with common materials

Thermal resistance R of individual materials

Thermo cover - R = 1.4 m2K / W

Solid bricks 60 cm R = 0.78 m2K / W

Polystyrene Facade EPS70 - th. 60 mm - R = 1.54 m2KW

Aerated concrete width 15 cm - R = 1.36 m2K / W

The task of thermoregulatory packaging is to reduce the peaks of temperature extremes, or to insulate goods for short shipments within 24 hours according to the required temperatures. Thermoregulatory packaging or thermoregulatory inserts can often replace an expensive reefer container. Which can be a big cost savings for a given company. To give you an idea, it is possible to realize that thanks to our thermoregulatory packaging, you protect the goods as if you were covering them with facade polystyrene, th. 60 cm, or surrounded with aerated concrete 15 cm thick.

5. Transport of liquid in a container using Flexi Tanks

Sopack s.r.o. offers a unique and economical solution for the transport of liquids in a container. We are able to help you with the transport of up to 24,000 liters of liquids in a 20-foot container. We will advise you on which Flexi Tank to choose, and we will mainly install Flexi Tank for you, or we will train you so that you are sure that you are installing the Flexi Tank correctly. Flexi Tank is a multi-layered "bag" square shaped that has a 3 inch valve for filling. It consists of a PPW protective layer of double LDPE layers and a double PE layer with Food Grade certification.

6. Efficient transport of bulk materials using container liners

Sopack s.r.o. offers liners for containers for the transport of bulk materials, such as sugar, malt, technical materials, corn, rice. Container liners turn the container into an efficient storage for bulk materials. Sopack s.r.o. They will advise and recommend a suitable loading, a suitable container insert. They will teach you how to fill and insert the insert correctly.